The Shaanxi NITYA AAC panel production line project is a key demonstration of Teeyer’s technological capabilities, representing the advanced manufacturing level of China’s AAC panel industry. The entire AAC production line is equipped with Teeyer’s independently developed automatic networking workstation and wet separation system, both of which are at the intentional advanced manufacturing level. By adopting energy-saving and environmentally friendly processes throughout the whole production flow, the project achieves a deep integration of high efficiency, high stability, and green manufacturing.

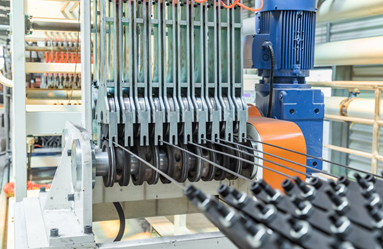

During the batching, casting, and pre-curing stages, the AAC production line introduces Teeyer’s automatic networking workstation, enabling fully automated processing of reinforcing steel mesh for panels throughout the entire workflow. The concrete production line system integrates functions including automatic dowel cleaning and replacement, automatic clip feeding, automatic mesh frame gripping and precise positioning, automatic clip fastening, automatic mesh circulation, and automatic mesh assembly. This greatly reduces manual intervention and ensures a high level of consistency in networking quality.

The automatic networking workstation features high compatibility and can accommodate steel meshes and clips of various specifications, meeting the requirements of different panel types and product configurations. While substantially reducing labor costs and improving production efficiency, it also enhances process stability and operational safety, laying a solid foundation for the stable production of high-quality concrete panels.

In the cutting section, the AAC production line is equipped with Teeyer’s independently developed wet separation system. The system integrates conveying, lifting, and precise positioning functions, and optimizes the operating cycle of the separation stations, significantly improving overall operational efficiency.

Through intelligent adjustment of the separation support positions, high-precision separation of green bodies is achieved. Combined with a real-time quality inspection system, the wet separation system effectively addresses common industry challenges such as green body adhesion and finished product damage in AAC production. The product qualification rate is significantly improved, providing customers with a more efficient, stable, and reliable production solution. The newly developed separation transmission technology enables a qualitative improvement in the overall quality of AAC panels.

The autoclaving section strictly controls curing process parameters to ensure that panel strength, dimensional stability, and long-term performance meet high-standard requirements, providing reliable assurance for finished product quality.

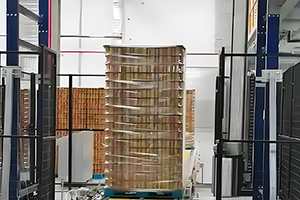

During the finished product packing section, the AAC production line realizes efficient panel arrangement, automatic packaging, and standardized output, meeting the requirements of large-scale, continuous production and transportation.

The Teeyer Shaanxi NITYA AAC panel production line project has successfully created a modern demonstration production line integrating high-end manufacturing, intelligence, high efficiency, and green production, and has become a benchmark model for efficient and environmentally friendly production of high-end AAC panels in China.

-

- Raw Material Processing SectionAs the first part of the AAC block production line, the raw material preparation section includes several...

-

- Automatic Steel Mesh Fabricating and Circulating SectionThe straightened steel bars are welded into steel mesh automatically...

-

- Pouring & Pre-Curing SectionIn the batching and pouring section, you can find a range of related machines including...

-

- Cutting SectionThe pre-cured concrete block in the mould will be cut into pieces as needed by the AAC cutting machine. ...

-

- Autoclaving SectionThe autoclaving section is a critical part of the entire AAC production line. It includes traction mechanism...

-

- Finished Products Packing SectionDCS automation control system is composed of Siemens PLC hardware, that is decentralized ...

English

English English

English English

English Русский

Русский Español

Español العربية

العربية العربية

العربية Indonesia

Indonesia فارسی

فارسی