Raw Material Processing Section

As the first part of the AAC block production line, the raw material preparation section includes several machines like jaw crusher, ball mill, bucket elevator, etc. Each machine is perfectly integrated into the production line.

-

- Slurry AgitatorThere is a transition slurry pool next to the slurry storage tank, with two functions: one is to pump slurry to batching area, the other is to make connection with each single tank. Read More

-

- Slurry Storage TankAfter ball mill, the slurry will be pumped to the slurry storage tank, the agitator of tank will work constantly to avoid slurry sedimentation.Read More

-

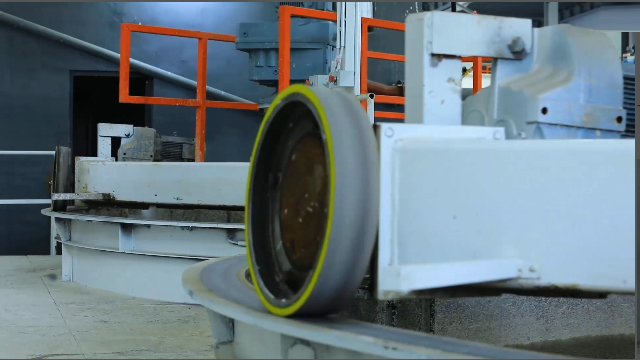

- Jaw CrusherThe jaw crusher is an important machine for the raw material preparation section. It is mainly used to crush lime into powder for AAC production.Read More

-

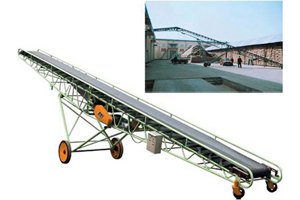

- Belt ConveyorThe belt conveyor, just like the bucket conveyor, is a very important material conveying equipment for the autoclaved aerated concrete... Read More

-

- Bucket ElevatorThe bucket elevator is an important material conveyor system for the autoclaved aerated concrete block/panel production line. It features big conveying capacity...Read More

-

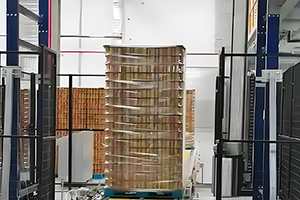

- Powder Storage SiloThe power storage silo is quite important for the material storage in an AAC production line. It is suitable for storing dried granule and powder...Read More

-

- Dust CollectorThis dust collector can be used as a dust collecting device at the top or bottom of various storehouse, silo, and conveying machine.Read More

English

English English

English English

English Русский

Русский Español

Español العربية

العربية العربية

العربية Indonesia

Indonesia فارسی

فارسی