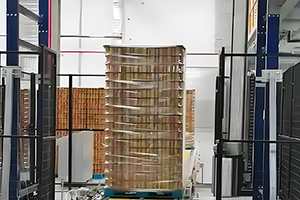

Tiling Hoister

After pre-curing, the mould will be transferred to tiling area. The hoister should grasp mould to rotate it with 90 degrees, then the clamping arm controlled by hydraulic motor will loosen to put side wall and cake together on the cutting cart. Then the empty mould base will be sent back to the side wall conveyor line, which is assembled with a free side wall to become a complete mould and ready for the next pouring processing.

The tilting table is installed at the end of the cutting section. By using this equipment, the waste material at the top and bottom of cake can be removed. The tilting table is composed by a table, guide pillar, hydraulic system, and control system.

The cut concrete block, together with the side plate is conveyed to the table by the semi-finished product hoist. Then the side plate will be fixed, while the block will be turned by 90° by the hydraulic system. Thus the waste material can fall off automatically. After that, the table rotates back to the original position, and releases the side plate.

To make our tilting table more reliable, we use premium oil cylinder. Thus the table can tilt stably and synchronically, while the tilting speed is also adjustable. The whole tilting process doesn't need the traveling crane, and little operation is needed from the workers.

Get In Touch

Jiangsu Teeyer Intelligent Equipment Co., Ltd. is a high-tech enterprise specialized in building materials equipment designing, R&D, manufacturing, project management and integration of operation & maintenance. The main product of TEEYER is the whole line equipment for AAC block and panel production. TEEYER aims to provide customers with satisfactory overall solution for wall material products.

Located in High-tech Zone, Changzhou City, TEEYER Company set up in the year of 1989, with 160.7 million yuan registered capital, 143,000 square meters covering area, and over 400 employees, among them more than 80 administrative staff and senior R&D technicians.

-

- Automatic Gas Distribution and Residual Gas Recovery SystemAccording to the set value, the automatic steam distribution system will adjust valve...

-

- SeparatorTo separate the sticky cakes into several layers, the finished products are blocks or panels. The separator is an important...

-

- Finished Product Clamping HoistFinished products will be lifted by clamping hoister, to leave side wall behind, and the side wall will be transferred...

-

- Rotating HoisterFinished squeezed, blocks will be lifted by rotating hoister, on the length 1.2m direction, after 90 degree rotating, the blocks will be put in cross directions on the pallet.

-

- Finished Product Conveyor LineThe finished product conveyor line is used for block conveying at the packaging section. As a chain conveyor...

English

English English

English English

English Русский

Русский Español

Español العربية

العربية العربية

العربية Indonesia

Indonesia فارسی

فارسی