Ball Mill

Raw material includes sand, fly ash and tailings to be milled into fine material, in order to meet the slurry standards.

The inlet is equipped with control valve and flowmeter to control the water flow. The sand is weighed by the belt scale, and the ratio of water and sand is automatically controlled by the computer.

The ball mill is a necessary part of the raw material preparation section. There are two kinds of ball mill in an AAC production line: wet type and dry type. Wet type ball mill is used to mill sand while the dry type is for lime stone.

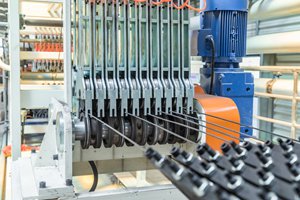

The ball mill comprises several main parts, like feeding part, discharging part, rotating part, transmission part (gear reducer, small transmission gear, motor, electronic controller). The hallow shaft is made from casting steel parts, and its lining is interchangeable. The big rotating gear is processed with casting steel parts by gear hobbing. The inner wall of the barrel is embedded with an anti-wear lining plate. In general, this ball mill is stable and reliable for the milling operation.

- Wet Type Ball Mill

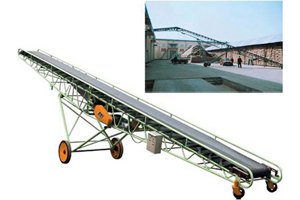

Sand (or fly ash, gypsum) is conveyed to the ball mill by electromagnetic vibration conveyor and belt conveyor. After milling, the material will be pumped to the slurry storage container. - Dry Type Ball Mill

Lime is conveyed to the jaw crusher by electromagnetic vibration feeding machine and belt conveyor. After crushing, the material will be conveyed to the lime storage silo by the bucket conveyor. Then the lime gravel will be transferred to the ball mill through a screw conveyor. The grinded material then will be conveyed to the powder storage silo by spiral conveyor screw conveyor and bucket conveyor.

| Model | Rotating speed (rpm) | Steel ball (ton) | Original material size (mm) | Final material size (mm) | Production capacity (ton/h) | Power (kW) | Weight (ton) |

| 38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 | 3.6 | |

| 38 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 4.6 | |

| 32 | 3.8 | ≤25 | 0.075-0.6 | 1.5-4.8 | 45 | 12.5 | |

| 32 | 5 | ≤25 | 0.074-0.4 | 1.6-5 | 45 | 12.8 | |

| 32 | 7 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 | |

| 27 | 8 | ≤25 | 0.074-0.4 | 2-5 | 90 | 17 | |

| 27 | 14 | ≤25 | 0.074-0.4 | 3-6 | 110 | 21 | |

| 27 | 15 | ≤25 | 0.074-0.4 | 3.5-6 | 132 | 2407 | |

| 24 | 11 | ≤25 | 0.074-0.4 | 4-10 | 180 | 28 | |

| 24 | 23 | ≤25 | 0.074-0.4 | 6.5-15 | 210 | 34 | |

| 24 | 25 | ≤25 | 0.074-0.4 | 7.5-17 | 245 | 36 | |

| 21 | 30 | ≤25 | 0.074-0.4 | 10-22 | 370 | 48.5 | |

| 21 | 30 | ≤25 | 0.074-0.4 | 14-26 | 380 | 52.8 | |

| 21 | 33 | ≤25 | 0.074-0.4 | 16-29 | 475 | 56 |

Get In Touch

Jiangsu Teeyer Intelligent Equipment Co., Ltd. is a high-tech enterprise specialized in building materials equipment designing, R&D, manufacturing, project management and integration of operation & maintenance. The main product of TEEYER is the whole line equipment for AAC block and panel production. TEEYER aims to provide customers with satisfactory overall solution for wall material products.

Located in High-tech Zone, Changzhou City, TEEYER Company set up in the year of 1989, with 160.7 million yuan registered capital, 143,000 square meters covering area, and over 400 employees, among them more than 80 administrative staff and senior R&D technicians.

-

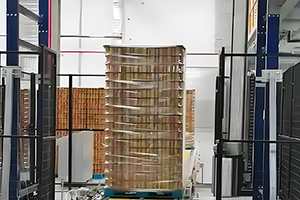

- Mesh Welding MachineThe straightened steel bars are welded into steel mesh automatically, which is used for the preparation...

-

- Wax-dipping Lifting DeviceAssembled steel frames with steel pins together to be lifted by this device, dipping into wax, it will help to prevent...

-

- Dowel-Inserting and Dowel-Drawing Out HoisterAssembled steel frames or steel cages are inserted in mould then pull out from mould...

-

- Mesh Assembly Frame Conveyor LineThis conveyor line consists mesh assembly frame rack, mesh assembly frame ferry cart...

-

- Anticorrosive Liquid Dipping and Drying SystemThe dipping hoister will carry assembled frames and cages to put them into anticorrosive...

English

English English

English English

English Русский

Русский Español

Español العربية

العربية العربية

العربية Indonesia

Indonesia فارسی

فارسی