Taizhou Jintai Environmental Thermal Power Co., Ltd., located in Binjiang Industrial Park, Taizhou City, Jiangsu Province, is a modern environmentally friendly high-tech private joint-stock enterprise founded in 2002.

The company takes "energy saving and consumption reduction, cost reduction and efficiency increase" as the business principle. Jintai has established an integrated energy cycle industry chain that utilizes resources efficiently, regenerates and recycles the waste produced in thermal power plants. It has set up a new building materials branch to manufacture and sell new construction materials.

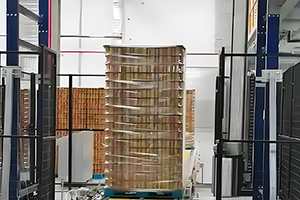

Jintai purchased autoclaved aerated concrete block production equipment from Teeyer to create a high-level fully automatic AAC panel production line in China, with an annual production capacity of 350,000 square meters of AAC blocks and panels. The production line was officially put into operation in 2021.

Teeyer’s standardized 6m*1.2m*0.6m fully automatic AAC block & panel production line

Teeyer’s standardized 6m*1.2m*0.6m fully automatic AAC block & panel production line

Focusing on recycling raw material and saving energy, Teeyer has developed a vacuum suction hood mounted on the vertical cutting machine and added a conveyor for dry materials under the tilting table to ensure the efficiency of waste recycling. Compared with previous set-up, this change will avoid slurry splashing during tilting and provide a better working environment. In addition, it also assists in improving the stability of equipment operations.

The tilting table uses cake auto-shifting technology, solving the problems including reciprocating grouping crane operations and long-time waiting for the handling of the cake. It greatly improves the production efficiency of the whole line, and the production cycle is shortened by 1min/mould. The overall production capacity is increased by 25%.

Double-station and dry material conveying tilting table, improving the production efficiency, ensuring the tidiness of the workshop

Double-station and dry material conveying tilting table, improving the production efficiency, ensuring the tidiness of the workshop

The autoclave steam distribution system is easy to operate and does not require much skill. The operation is simple: operators only need to close the door of the autoclave, then select functions on the computer following pre-determined processes (e.g., block type, thin panel type, thick panel type), and press a button to start the corresponding autoclave number. The system also increases the security of the steam distribution. A safety interlocking procedure is provided between the steam distribution valve and the autoclave door opening device, with an extra sound and light alarm device. If the door is not completely closed, steam will not enter, and if there is steam present, the door cannot be opened. The steam recovery system of the autoclave is linked with an automatic steam distribution system for automatic operation, saving labor costs.

The automatic steam distribution system highlights the automation of production line, improving the safety of equipment

The automatic steam distribution system highlights the automation of production line, improving the safety of equipment

After adopting an autoclave residual vapor recovery system, the energy-saving index of the autoclave reaches more than 20%. The hot water can be used to maintain a regulated environment in the pre-curing room and the steel bar drying room, without using fresh steam, which saves energy and reduces consumption.

The residual steam recovery system can also facilitate the utilization of condensed water that is discharged from the autoclave. At the high temperature stage, the heat in the condensed water is recycled for heating the preconditioning room and the curing room before autoclaving.

Energy saving and emission reduction are significant target of Teeyer’s modern plant

Energy saving and emission reduction are significant target of Teeyer’s modern plant

The Jintai project coincided with the outbreak of the Covid-19 pandemic in China, presenting a severe challenge for its implementation. During the pandemic, Teeyer project service team overcame many difficulties, such as physical isolation, nucleic acid testing, staff fever and illness. The logistics team also overcame numerous obstacles to successfully complete the delivery, installation, commissioning, and start-up of the equipment. Their efforts earned recognition and satisfaction from Jintai's senior management team.

Teeyer’s excellent project service team, satisfies every after-sales needs from clients

Teeyer’s excellent project service team, satisfies every after-sales needs from clients

-

- Raw Material Processing SectionAs the first part of the AAC block production line, the raw material preparation section includes several...

-

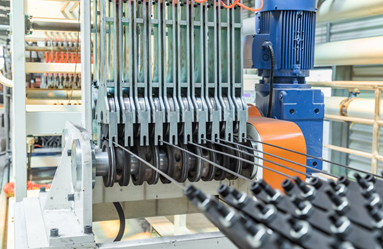

- Automatic Steel Mesh Fabricating and Circulating SectionThe straightened steel bars are welded into steel mesh automatically...

-

- Pouring & Pre-Curing SectionIn the batching and pouring section, you can find a range of related machines including...

-

- Cutting SectionThe pre-cured concrete block in the mould will be cut into pieces as needed by the AAC cutting machine. ...

-

- Autoclaving SectionThe autoclaving section is a critical part of the entire AAC production line. It includes traction mechanism...

-

- Finished Products Packing SectionDCS automation control system is composed of Siemens PLC hardware, that is decentralized ...

English

English English

English English

English Русский

Русский Español

Español العربية

العربية العربية

العربية Indonesia

Indonesia فارسی

فارسی