Mold and Side Plate

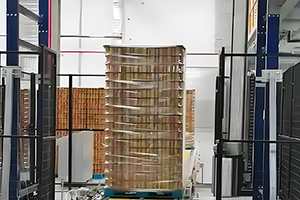

The mould is a recyclable part for AAC production line. Together with side plate, the AAC block mould or AAC panel mould is used for holding the slurry material from the pre-curing section to the cutting section.

The needed type and quantity of the mould depend on the expected annual production capacity. Our mould consists of steel channel and steel plate, so it is strong and durable. Forging wheels are available at the bottom. Sealing strips are also fixed to avoid the leakage of the poured material.

Side plate, working together with mould, is a necessary part for an AAC production line. After de-moulding, the side plate carries the green cake to cutting, grouping, autoclaving and packaging. Our side plate is welded by U channel steel, H channel steel, steel pipe and steel plate. The structural performance is excellent. After several years of use, limited deformation will be observed.

Get In Touch

Jiangsu Teeyer Intelligent Equipment Co., Ltd. is a high-tech enterprise specialized in building materials equipment designing, R&D, manufacturing, project management and integration of operation & maintenance. The main product of TEEYER is the whole line equipment for AAC block and panel production. TEEYER aims to provide customers with satisfactory overall solution for wall material products.

Located in High-tech Zone, Changzhou City, TEEYER Company set up in the year of 1989, with 160.7 million yuan registered capital, 143,000 square meters covering area, and over 400 employees, among them more than 80 administrative staff and senior R&D technicians.

-

- Cutting CarThe AAC cutting car system works around the cutting station. It consists of a cutting car, pinion and rack moving rail. In the cutting section...

-

- Tongue and Groove Milling DeviceCutting cart carries side plate and cake to the tongue & groove area, to cutting the cake both two sides. Generally...

-

- Vacuum Suction HoodThe vacuum suction hood is used to clean the waste produced during the AAC production. It is mounted on the vertical cutting machine...

-

- Tiling HoisterAfter pre-curing, the mould will be transferred to tiling area. The hoister should grasp mould to rotate it with 90 degrees, then the clamping arm controlled...

-

- Top and Bottom Cleaning SystemAfter cutting processing, the waste material retained at the bottom or top of the cake should be recycled into waste pulp...

English

English English

English English

English Русский

Русский Español

Español العربية

العربية العربية

العربية Indonesia

Indonesia فارسی

فارسی